Did you know that the global battery market is projected to reach a staggering $100 billion by 2025? That's right! With electric vehicles (EVs) taking over our roads, the largest battery manufacturers are at the forefront of this electrifying revolution. But what makes these giants stand out in terms of transportation attributes? Buckle up as we dive into their fascinating world!

The Powerhouses: Largest Battery Manufacturers and Their Transport Features

The largest battery manufacturers, such as CATL, LG Chem, and Panasonic, have transformed how batteries are transported across the globe. These companies not only produce high-capacity batteries but also excel in logistics efficiency. They utilize advanced tracking systems to monitor shipments in real-time while employing strategic partnerships with shipping companies for faster delivery times. Additionally, they implement robust inventory replenishment strategies that ensure optimal stock levels are maintained throughout their supply chains—keeping production lines running smoothly without interruptions.

Diving Deeper: Electric Vehicle Components and Inventory Replenishment Strategies

When it comes to electric vehicle components, these large manufacturers adopt sophisticated inventory replenishment strategies tailored specifically for EV needs. For instance, they forecast demand based on market trends and historical data to avoid shortages or excess stock. Moreover, they often use just-in-time (JIT) practices which minimize storage costs while ensuring timely availability of essential components like lithium-ion cells and modules. This meticulous planning allows them to respond swiftly to fluctuations in demand while maintaining a competitive edge.

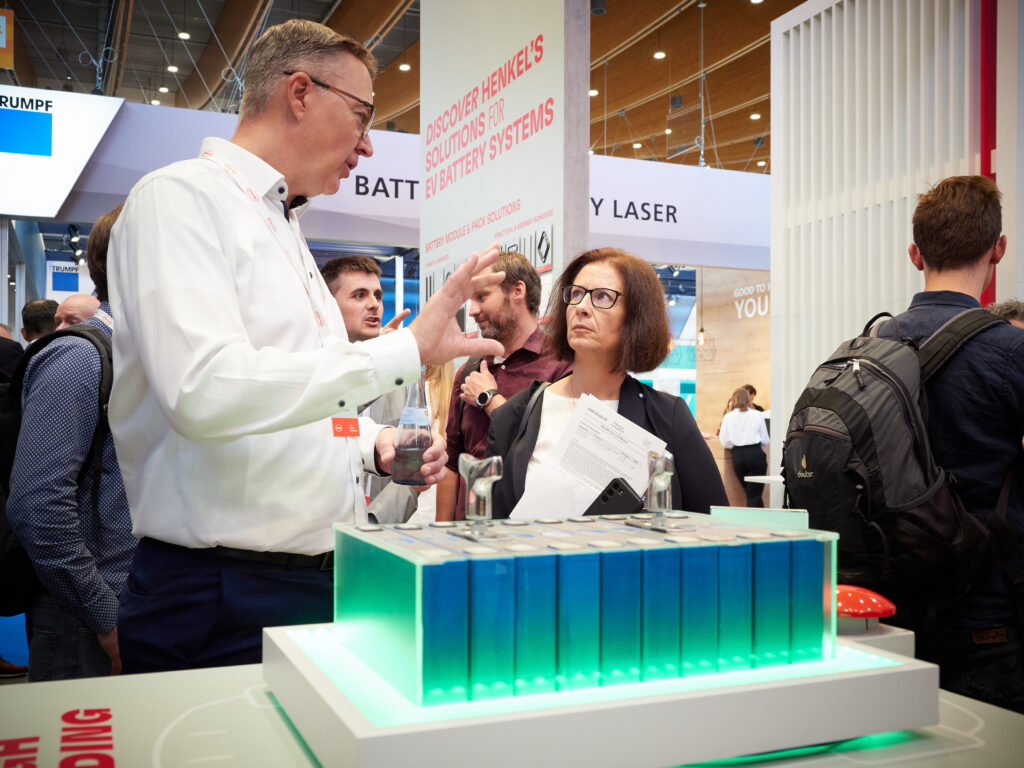

The Battery Show: A Showcase of Inventory Replenishment Strategies

The Battery Show serves as an incredible platform highlighting innovative inventory replenishment strategies employed by leading battery manufacturers:

- Networking Opportunities: The event brings together industry leaders who share insights on best practices for managing inventories effectively.

- Workshops & Seminars: Attendees can participate in sessions focused on cutting-edge technologies that enhance supply chain management.

- Sustainability Focus: Many discussions revolve around eco-friendly practices within inventory processes—an increasingly important aspect today!

- User-Friendly Software Solutions: Exhibitors showcase software tools designed specifically for optimizing inventory control systems.

- Circular Economy Practices: Emphasis is placed on recycling materials from old batteries—a crucial step towards sustainable manufacturing!

Your Takeaway: Conclusion on Largest Battery Manufacturers' Inventory Replenishment Strategies

The largest battery manufacturers are not just about producing powerful energy solutions; they're also masters at navigating complex transport attributes through effective inventory replenishment strategies. By leveraging technology and innovative approaches tailored for electric vehicle components, they ensure seamless operations from factory floor to final destination. As we continue embracing this electrified future, it's exciting to see how these giants will evolve further—and I can't wait to witness what's next!