Double Wall Fabric Manufacturers have gained significant attention for supplying advanced textiles used in high-performance and structural applications. While manufacturers play an essential role in ensuring production consistency and innovation, the true value lies in the capabilities of double wall fabric itself—a specialized material designed to deliver strength, flexibility, and lightweight support in a single package.

What is Double Wall Fabric?

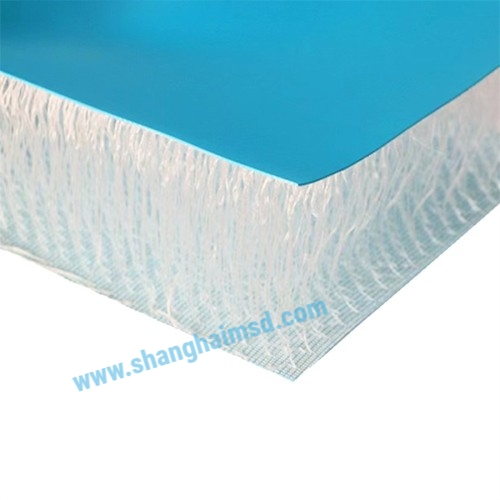

Double wall fabric, sometimes referred to as drop stitch fabric, is a unique textile construction composed of two layers of fabric connected by vertical fibers. When pressurized with air or fluid, these connecting fibers maintain a consistent distance between the layers, creating a flat, rigid surface. This structure allows the fabric to withstand high internal pressures while remaining incredibly light—making it ideal for inflatable applications like stand-up paddleboards, rescue equipment, portable structures, and airbeds.

One of the key benefits of double wall material is its versatility. It can be customized in terms of thickness, coating type (PVC or TPU), and fiber density, depending on the end-use requirements. Its high strength-to-weight ratio enables engineers and designers to create products that are not only strong and durable but also easy to transport and store.

Applications Across Multiple Industries

The adaptability of this textile has made it indispensable in various industries, from sports and recreation to military and emergency response. In marine and aviation sectors, for instance, double wall fabric is often used in inflatable boats and aircraft hangar floors. In the medical field, the fabric is valued for use in inflatable medical tents and emergency shelters, offering rapid deployment and high durability.

Additionally, manufacturers are constantly working to improve coatings and fabric bonding techniques to enhance airtightness and resistance to environmental conditions. Some newer variations include UV-resistant coatings and anti-mildew treatments, which extend the fabric’s lifespan in harsh outdoor environments.

What to Look for in a Quality Supplier

While the product is technical in nature, selecting a trusted double wall fabric supplier ensures reliability in performance, material safety, and design precision. Manufacturers who invest in R&D can offer more than just standard specifications—they provide tailored solutions, compliance with international standards, and materials that evolve with the latest engineering demands.

By working closely with experienced suppliers, customers gain access to advanced laminating techniques, rigorous testing protocols, and quality consistency that’s crucial for critical-use products. Whether for recreational gear or emergency equipment, choosing the right partner ensures that the final product performs as expected under pressure—literally.

To learn more about high-quality double wall fabrics and explore customized options for your business, visit shanghaimsd.com for expert insights and innovative materials that meet global standards.