Disposable Kraft Box Factory: Pioneering Sustainable Solutions for Modern Food Industries

As the global food sector increasingly prioritizes sustainability, the disposable kraft box Factory has emerged as a cornerstone of eco-conscious packaging, particularly for takeout, fast food, and ready-to-eat markets. Balancing durability, environmental responsibility, and cost-efficiency, these factories are reshaping how the industry meets consumer demand while addressing pressing challenges like material innovation and regulatory compliance.

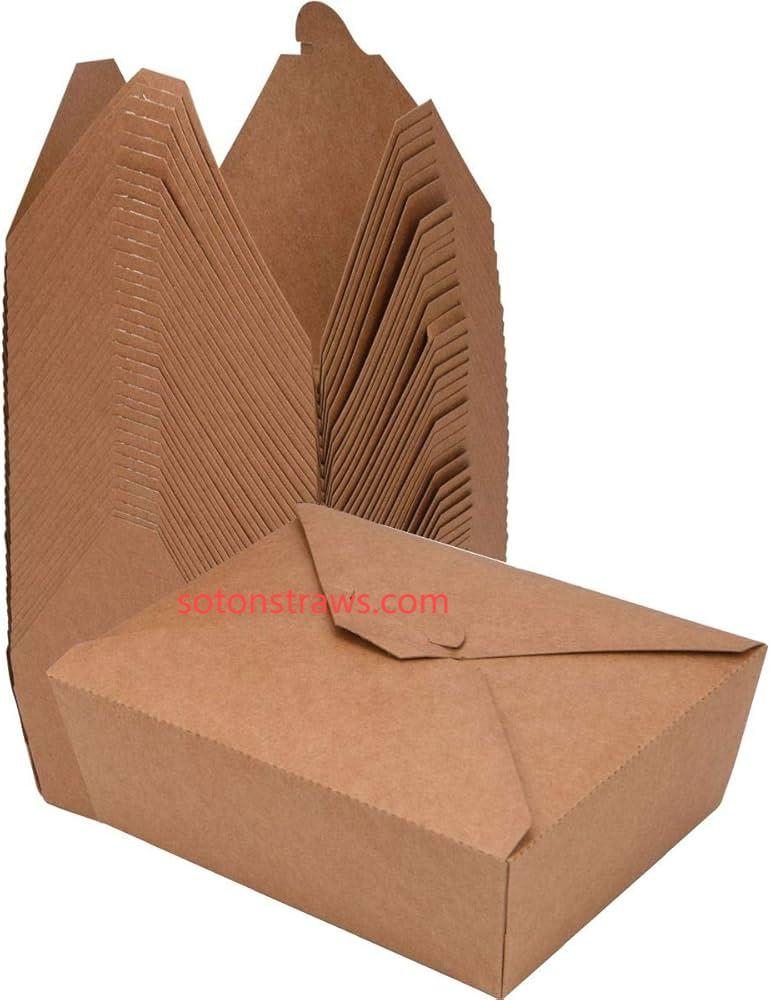

The appeal of disposable kraft boxes lies in their versatility and alignment with circular economy principles. Made from renewable resources like FSC-certified kraft paper or agricultural residues, they offer compostability and reduced environmental footprints compared to traditional plastics. Their applications span greasy burgers, delicate sushi, hot soups, and even artisanal baked goods, maintaining structural integrity while preventing leaks—a critical feature for both consumer satisfaction and brand reputation. However, rising competition demands continuous innovation. Factories now integrate water-based inks and plant-based adhesives to eliminate toxic chemicals, ensuring compliance with FDA and EU food-contact standards. Advanced coating technologies, such as PLA laminates, enhance grease resistance without compromising biodegradability, addressing durability concerns in diverse culinary scenarios .

Certifications remain a gateway to international markets. Adherence to FSC, ISO, and regional food-safety regulations not only builds trust but also unlocks opportunities in regions with strict green trade policies. Blockchain-enabled traceability systems further enhance transparency, allowing brands to verify sustainable sourcing from forest to finished product—a key differentiator for eco-conscious buyers.

Design innovation is another frontier. Customizable shapes, sizes, and branding options cater to niche markets, from luxury hotel bento boxes to budget-friendly fast-food packaging. Interactive elements like QR codes educate consumers on disposal practices, bridging the gap between usability and environmental stewardship. Meanwhile, modular production lines enable rapid shifts between regional preferences, such as sugarcane-based materials in tropical markets or wheat straw blends in temperate zones.

Looking ahead, factories are investing in closed-loop systems to recycle post-consumer waste into new batches, minimizing reliance on virgin materials. Partnerships with composting facilities and urban waste management programs ensure end-of-life solutions, aligning with global carbon neutrality goals. By merging technological agility with ecological ethics, the disposable kraft box Factory is not just adapting to change—it’s leading a packaging revolution where sustainability and profitability thrive in unison.

sotonstraws.com