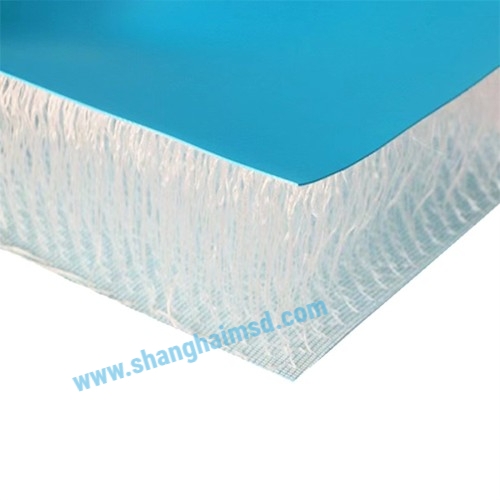

As the demand for more resilient and environmentally friendly materials increases, many buyers and designers are re-evaluating their options with a focus on modern alternatives. Among these, manufacturers of Double Wall Fabric have increasingly turned to thermoplastic polyurethane (TPU) coatings as a progressive solution. TPU coatings offer a range of advantages over traditional polyvinyl chloride (PVC) options, influencing applications across inflatable structures, water sports equipment, and industrial textiles.

Why TPU is Gaining Ground Over PVC

Thermoplastic polyurethane is known for its superior mechanical properties and flexibility. When applied to Double Wall Fabric, TPU delivers enhanced tensile strength and elongation capacity, making it suitable for repeated inflation and deflation without material fatigue. Unlike standard PVC-coated fabrics, TPU-coated versions are less prone to cracking in cold temperatures and maintain their elasticity over time.

Additionally, TPU offers superior abrasion resistance. This is critical for applications like inflatable boats, tents, or rescue platforms where friction with rough surfaces is common. The performance consistency of TPU coatings contributes directly to the overall reliability of the fabric, especially under pressure-bearing use cases.

Environmental and Health Considerations

One of the most compelling reasons behind the shift toward TPU-coated Double Wall Fabric is its environmental profile. TPU is generally more biodegradable than PVC and does not contain plasticizers such as phthalates, which are common in traditional coatings. With growing awareness and regulations targeting eco-friendly products, industries are favoring materials that meet both performance and sustainability standards.

TPU is also odorless and non-toxic, an important feature for fabrics used in consumer-facing or medical inflatable products. It also exhibits reduced smoke emission when burned, further enhancing its safety rating during production and use.

Improved Bonding and Customization Options

TPU's compatibility with modern adhesive technologies allows for seamless heat-welding and bonding. This reduces reliance on chemical adhesives and makes the finished Double Wall Fabric cleaner and more uniform. It also simplifies manufacturing and repairs, cutting down maintenance costs over time.

In terms of appearance, TPU coatings offer high transparency and smooth finishes, which can be especially useful when clear visuals or branding are important. The material can be dyed easily without fading, providing flexibility in design and color matching for custom projects.

A Smarter Material Choice

While PVC remains a cost-effective and widely available option, the benefits of TPU-coated Double Wall Fabric make it a leading contender in advanced applications. Buyers who prioritize durability, eco-friendliness, and performance in challenging conditions will find TPU a compelling upgrade.

To explore more TPU-based material solutions and flexible textile options, visit shanghaimsd.com .