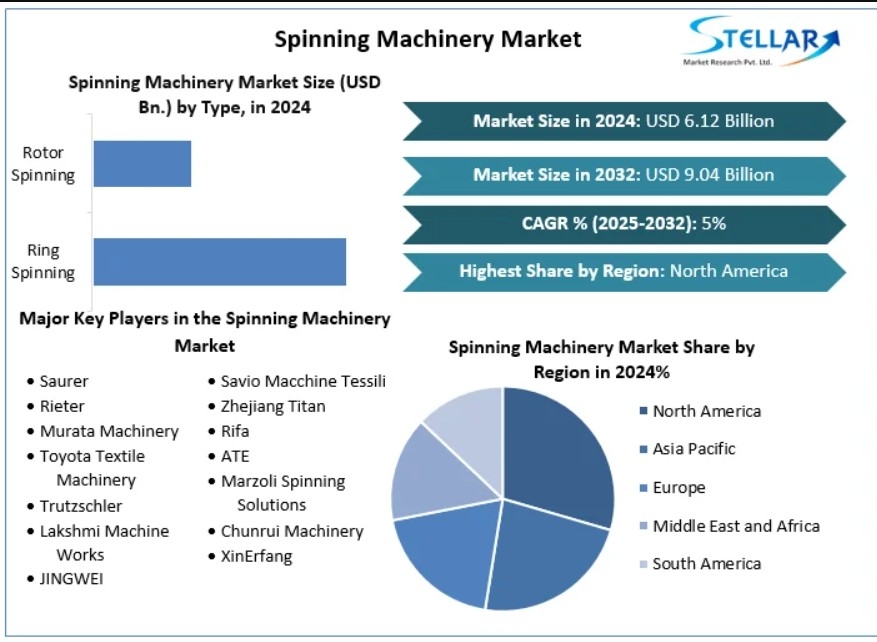

Spinning Machinery Market was valued at nearly US$ 6.12 Billion in 2024 and market size is estimated to grow at a CAGR of 5% and is expected to reach US$ 9.04 Bn. by 2032.during the forecast period. The growth is driven by rising global demand for textiles and garments, increasing adoption of automated spinning systems, and technological advancements that boost productivity and quality.

Free Sample Copy: https://www.stellarmr.com/report/req_sample/Spinning-Machinery-Market/201

- Market Estimation & Definition

The spinning machinery market refers to the global industry involved in the design, manufacturing, and distribution of machines that convert natural and synthetic fibers into yarn. These machines are fundamental to the textile value chain, enabling the production of high-quality threads used in apparel, home textiles, industrial fabrics, and technical textiles.

Spinning machinery includes a variety of systems such as ring spinning, rotor spinning, air-jet spinning, and carding machines, all critical in determining yarn characteristics like strength, fineness, and twist. With continuous modernization of textile mills and the integration of Industry 4.0 solutions, the global market is undergoing a dynamic transformation.

Free Sample Copy: https://www.stellarmr.com/report/Spinning-Machinery-Market/201

- Market Growth Drivers & Opportunities

1. Rising Global Textile Consumption

With an expanding middle class and rising disposable incomes, especially in Asia-Pacific and Africa, demand for textiles—ranging from apparel to home furnishings—is on the rise. This is pushing manufacturers to invest in high-capacity, efficient spinning equipment.

2. Automation and Smart Manufacturing

Textile manufacturers are increasingly turning to automated spinning systems to reduce labor dependency and operational costs. The use of AI, IoT, and cloud-based monitoring in spinning processes enables real-time quality checks, predictive maintenance, and energy efficiency.

3. Government Incentives in Developing Economies

Governments in key textile-producing countries like India, Bangladesh, Vietnam, and China are offering subsidies, tax reliefs, and export incentives to promote domestic textile manufacturing, which boosts demand for new spinning machinery.

4. Sustainability and Eco-Friendly Textiles

The shift toward organic, recycled, and sustainable textiles is prompting the development of spinning systems that can handle eco-fibers like bamboo, hemp, and recycled polyester, creating an avenue for innovation in machinery design and performance.

5. Global Fashion and Fast Apparel Trends

The global fashion industry's lean production cycles and the rise of fast fashion are creating a demand for spinning machinery that offers speed, precision, and flexibility to handle short-run, high-mix production scenarios.

- Segmentation Analysis (As per Stellar Market Research)

The Spinning Machinery Market is segmented based on Machine Type and Region:

By Machine Type:

- Ring Spinning

- Rotor Spinning

- Air-Jet Spinning

- Others

Ring Spinning currently dominates the market due to its ability to produce fine, strong, and high-quality yarn suitable for a wide variety of applications. However, Rotor Spinning is witnessing increased demand due to its lower energy consumption and higher production speeds, especially in mass-production settings.

Air-Jet Spinning, while still a niche segment, is gaining traction for its high-speed capabilities and low yarn hairiness, suitable for premium fabrics. The “Others” category includes open-end spinning and friction spinning machines, primarily used in specific industrial or technical textile applications.

By Region:

- North America

- Asia Pacific

- Europe

- South America

- Middle East & Africa

Asia Pacific dominates the global market due to its vast textile manufacturing base, with countries like India, China, Bangladesh, and Vietnam being top contributors. The region benefits from low production costs, a skilled labor force, and government support.

Europe and North America are focusing on sustainable textile production and automation upgrades, while South America and Africa present emerging opportunities as new textile hubs.

- Country-Level Analysis

United States

The U.S. spinning machinery market is modest in scale compared to Asia, but it is steadily growing due to:

- Rising investments in sustainable textiles

- Expansion of advanced textile materials used in healthcare, defense, and automotive

- Adoption of robotics and digital monitoring in yarn manufacturing

Companies in the U.S. are focusing on R&D for composite yarns and technical applications rather than mass-market fabrics. Partnerships between academic research institutions and machinery manufacturers are contributing to this innovation-led growth.

Germany

Germany remains a key hub for high-precision spinning machinery manufacturing, home to global leaders like Trützschler, Rieter, and Saurer. German-made machines are synonymous with quality and innovation, and are widely exported.

The German textile industry, though smaller in scale, is increasingly focused on technical textiles, which has led to the development of machinery tailored for synthetic and composite fibers. Moreover, Germany’s strong emphasis on Industry 4.0 integration is setting benchmarks in spinning automation and sustainability.

- Commutator Analysis (Competitive Landscape)

The spinning machinery market is highly competitive and technologically advanced, with several key players operating across different machine types and geographies. These players are investing in product innovation, automation, after-sales services, and regional expansion.

Key Companies:

- Rieter Holding AG (Switzerland)

- Saurer Group (Germany)

- Trützschler Group (Germany)

- Murata Machinery Ltd. (Japan)

- Toyota Industries Corporation (Japan)

- Lakshmi Machine Works Ltd. (India)

- Jingwei Textile Machinery Co., Ltd. (China)

Strategic Trends:

- Rieter recently unveiled a fully integrated ring spinning system with real-time digital controls, setting new standards for efficiency and flexibility.

- Saurer introduced a rotor spinning system with self-cleaning components, lowering downtime and maintenance costs.

- Lakshmi Machine Works (LMW), a dominant Indian manufacturer, continues to expand in Southeast Asia and the Middle East, offering cost-effective and energy-efficient solutions.

- Murata and Toyota Industries are emphasizing air-jet spinning machines capable of handling new-age fibers.

Emerging Players and Startups:

Startups in India and China are entering the market with modular spinning machines targeting SMEs and textile clusters. These compact systems require less capital investment and are easy to install and maintain, helping democratize access to modern spinning.

- Conclusion

The Global Spinning Machinery Market is entering a period of transformative growth, set to reach USD 9.10 billion by 2030, underpinned by automation, sustainability goals, and rising demand for textiles. From ring spinning systems to AI-integrated smart platforms, innovation is shaping the industry’s future.

As countries like India and China scale production, and advanced economies like Germany and the U.S. focus on automation and technical yarns, the spinning machinery sector is becoming both broader in scope and deeper in specialization.

For machinery manufacturers, textile companies, and investors, this is a moment of significant opportunity. A shift toward automated, sustainable, and efficient spinning solutions is not just a market trend—it’s the new global standard. Players who can adapt and innovate rapidly will define the future of this essential sector.

About Us:

Stellar Market Research is a leading India-based consulting firm delivering strategic insights and data-driven solutions. With 119 analysts across 25+ industries, the company supports global clients in achieving growth through tailored research, high data accuracy, and deep market intelligence, serving Fortune 500 companies and maintaining strict client confidentiality.

Address

Phase 3, Navale IT Zone, S.No. 51/2A/2, Office No. 202, 2nd floor, Near, Navale Brg, Narhe, Pune, Maharashtra 411041

sales@stellarmr.com

Mobile

+91 9607365656