These machines are designed to work with different types of transparent films, including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and composite films. This versatility allows manufacturers to choose films based on product requirements, such as barrier properties, flexibility, or environmental friendliness.

Transparent films ensure high visibility of the product, which is important for marketing, while still offering good protection against dust, moisture, and minor impacts.

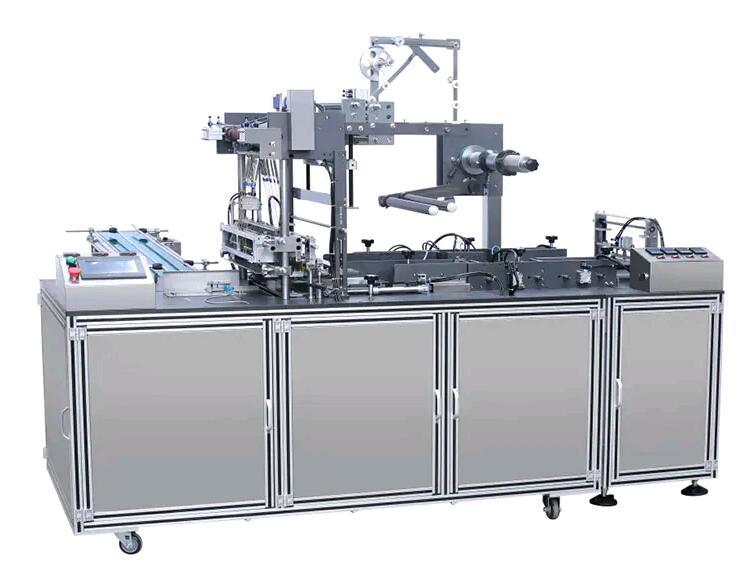

Modern three-dimensional transparent film packaging machines often feature high-speed automated operations, capable of packaging hundreds or thousands of units per hour depending on the model and product size. Automation reduces labor costs, improves consistency, and increases throughput, making it suitable for large-scale production environments.

Automation also includes features like automatic film feeding, cutting, sealing, and ejection, minimizing manual intervention and reducing error rates.

To ensure the package is secure and maintains its shape, these machines employ precise sealing technologies. Heat sealing is commonly used to bond the film edges tightly, preventing contaminants from entering and preserving product freshness or integrity.

The cutting mechanisms are designed to create clean edges that conform to the three-dimensional film shape, enhancing the overall presentation and ease of handling.

https://www.zjjwjx.cn/product/cellophane-wrapping-machine/jw280a-folding-transparent-film-wrapping-machine-with-anticounterfeit-easy-pull-line.html

Transparent film wrapping machine, its main basic functions include: on the basis of ensuring the quality of the packaging machine products, and greatly reducing the production cost and preparation cost of the packaging machine so that the machine and equipment at the price have a competitive advantage, to enhance competitive advantage. The transparent film wrapping machine is widely used for the three-dimensional packaging of transparent film in boxes of cosmetics, medicine, food, health products, audio-visual products, stationery, daily necessities, and so on (the packaging effect is the same as cigarettes).