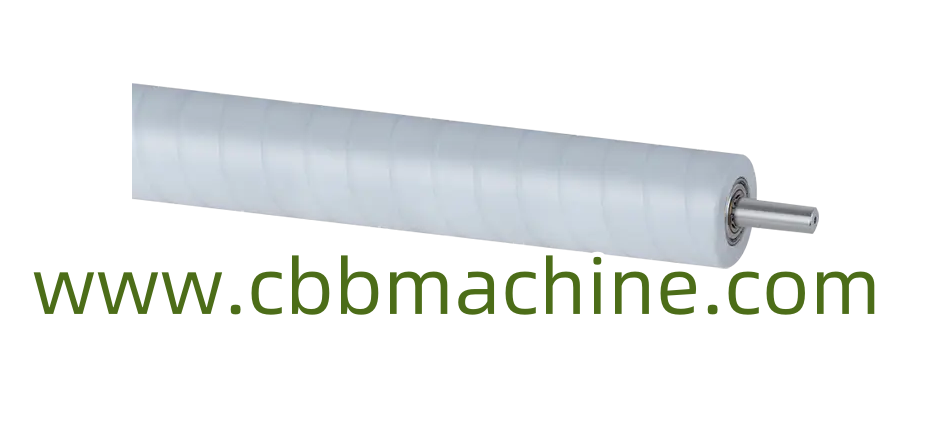

Precision manufacturing relies heavily on components like the Aluminum Roller , which serves a critical role in guiding, supporting, and smoothing web materials throughout various processing stages.

This type of roller is favored across industries due to its lightweight construction, corrosion resistance, and excellent dimensional stability. Whether in paper manufacturing, plastic film conversion, textiles, or packaging systems, aluminum rollers deliver consistent performance while keeping system weight low—an advantage in high-speed applications or machines requiring rapid acceleration and deceleration.

The strength-to-weight ratio of aluminum makes it a prime candidate for dynamic machinery. Unlike heavier steel alternatives, aluminum rollers offer faster response times, reducing inertia and improving energy efficiency. This property is particularly useful in industries where rapid direction changes are required, such as label printing or lamination lines.

In addition to performance advantages, aluminum offers excellent resistance to environmental factors. Its natural oxide layer protects it against moisture and many chemicals, meaning aluminum rollers perform well in humid or corrosive processing environments without the need for frequent maintenance or coatings.

CBBMACHINE specializes in the manufacture of custom aluminum rollers, catering to the exacting demands of global industrial clients. Their design team ensures each roller matches specifications in terms of diameter, surface finish, balance, and material tolerance. Whether you're running a lightweight foil or a thicker composite web, precision-balanced aluminum rollers from CBBMACHINE maintain alignment and prevent tracking issues that could compromise production quality.

Aluminum rollers can also be coated or anodized for added surface properties such as enhanced grip, reduced friction, or increased wear resistance. CBBMACHINE offers a variety of finish options tailored to customer needs, helping improve roller life and material compatibility.

One often overlooked benefit is the recyclability of aluminum. In an era of sustainable manufacturing, choosing aluminum rollers supports broader eco-friendly goals. Recyclable and energy-efficient, these rollers help operations lower their carbon footprint while maintaining the technical excellence needed for daily production.

Installation and integration of aluminum rollers into existing systems is straightforward. With CBBMACHINE’s engineering support, facilities can retrofit or upgrade their lines without costly redesigns. The company also provides guidance on bearing types, shaft connections, and balancing for maximum rotational stability.

For operations requiring minimal downtime and high-speed reliability, aluminum rollers offer an unbeatable blend of performance and practicality. When sourced from an experienced supplier like CBBMACHINE, these rollers become a strategic investment in productivity and product integrity.

To learn more about tailored aluminum roller solutions, visit https://www.cbbmachine.com/product/aluminum-roller/